Personalized Care, Optimized Results

Scroll downOur fully custom 3D printed braces help you optimize your practice by combining your expertise with our technology.

How We're Different

DESIGN AND DELIVER

A fully integrated system with 3D-printed ceramic braces and digital plans personalized to each patient allow doctors to visualize the end result and deliver in a whole new way.

YOUR TIME, YOUR FREEDOM

LightForce means faster treatment and fewer office visits. With greater efficiency per patient, you’ll get more time back. See the preliminary study.

MORE SMILING FACES

In addition to empowering your team by increasing staff involvement, the efficiency of LightForce can result in faster treatment times. This means a happier ortho team and a happier patient.

LightForce Technology

A Completely Personalized 7-7 System

FULLY CUSTOM BRACES

Introducing the world’s only fully personalized 3D printed bracket.

Features and benefits include a fully personalized base to fit the individual tooth morphology for better bond strength, complete freedom of motion, and much more.

LIGHTTRAY BY LIGHTFORCE

LightTrays are patient-specific indirect bonding (IBD) trays designed to create a truly personalized indirect bonding experience for patients and clinical teams.

LightTray empowers your clinical team to quickly and accurately bond each bracket with no doctor time required. The easy-to-edit trays feature identifiable arch segments and are pre-cut to precisely fit the patient’s teeth.

LightTray bonding jigs are only available for LightForce braces.

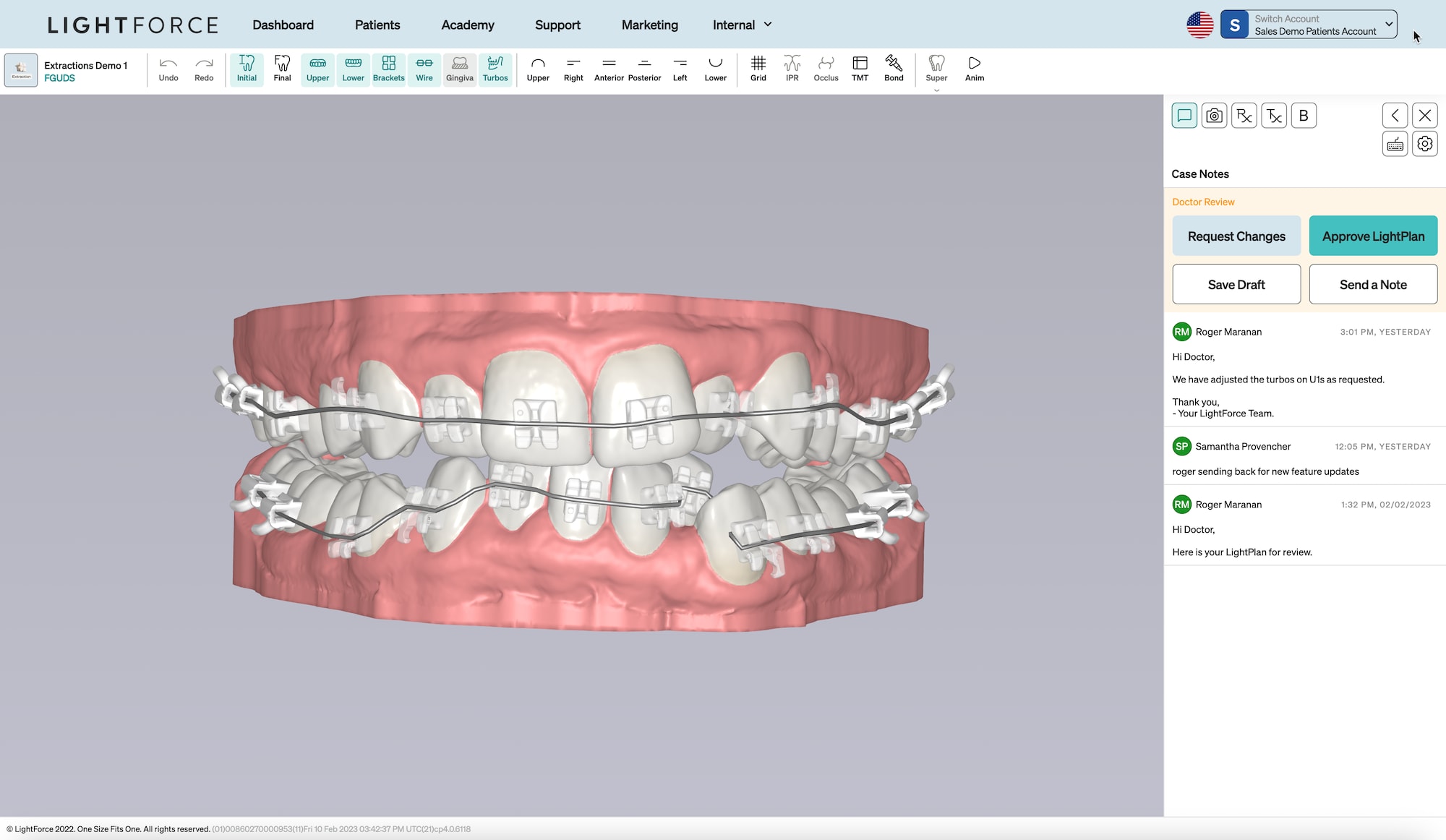

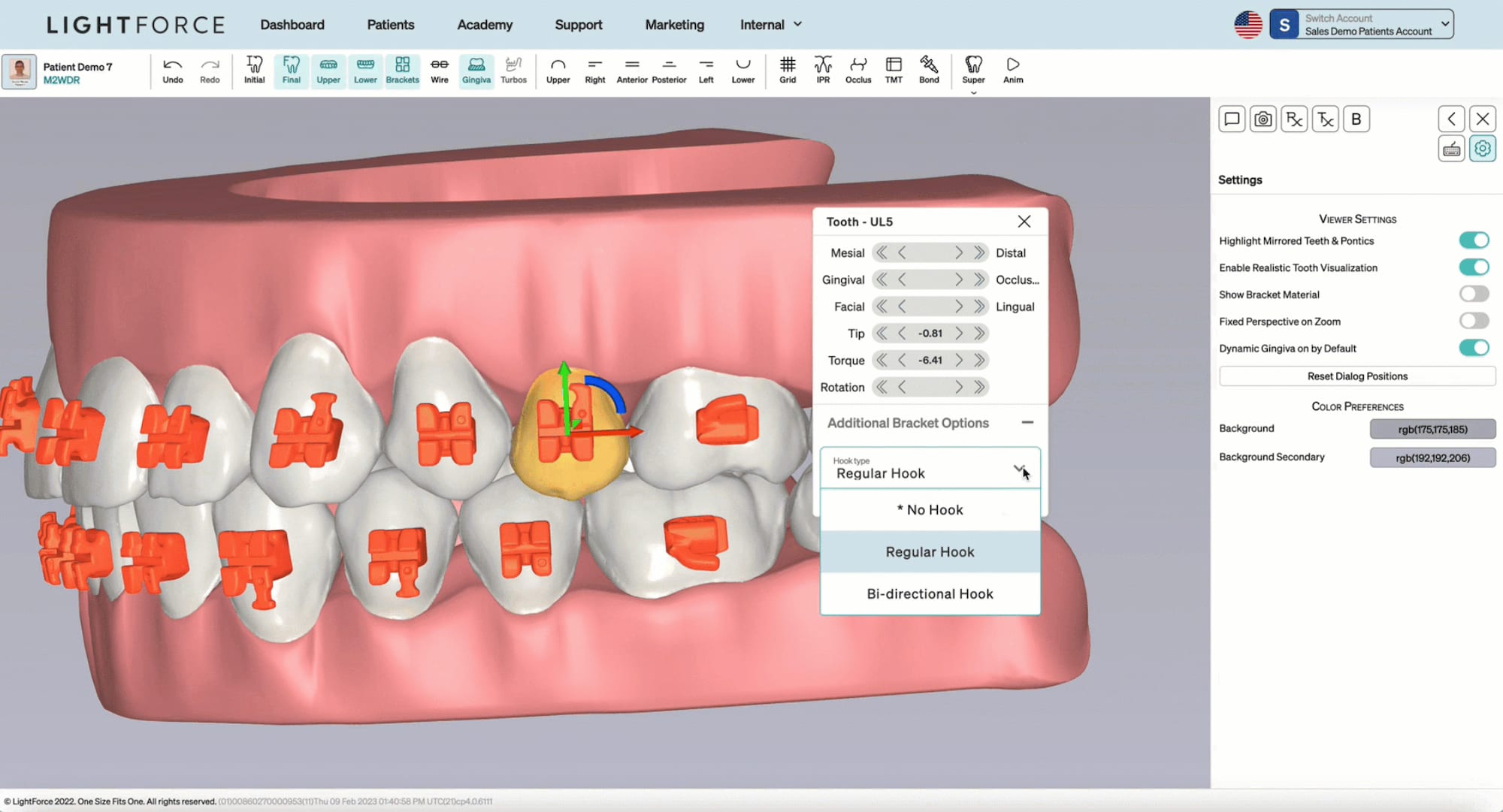

LIGHTPLAN SOFTWARE

LightForce’s web-based platform enables you to create, adjust, and approve treatment plans quickly and easily.

With complete control over every aspect of the treatment plan, the LightPlan software system empowers clinicians every step of the way.